码垛机器人常见的故障原因主要包括以下几个方面:

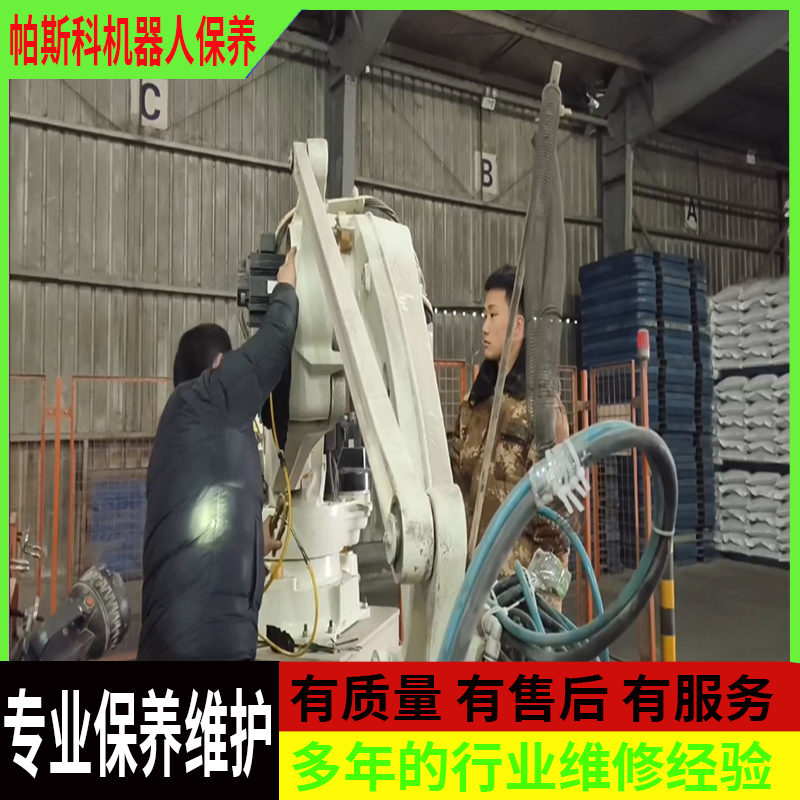

为了预防这些故障,建议定期对码垛机器人进行维护和检查,确保所有部件都在正常工作状态。同时,对于出现故障的机器人,应及时联系专业维修人员进行检查和维修,以确保其能够尽快恢复正常工作。

The common failure causes of palletizing robots mainly include the following aspects:

Overload failures: Overload failures can occur when a robot performs tasks that are beyond its design capabilities or tolerance. This can be caused by a collision between a tool or object at the end of the six axes and an external object, a motion monitoring trigger due to high viscosity of the lubricating oil, or an electromagnetic brake failure.

Overtravel failure: This usually occurs during the trial and may be due to the robot's range of motion exceeding the preset limits.

Serial Measuring Board SMB Data Loss: If the system is powered down for an extended period of time, the memory data may be lost after the battery is depleted, which may require recalibration of the mechanical zero position.

Electrical cabinet failure: The components in the electrical cabinet, such as the drive motor, the rotating shaft of the industrial circuit board, the switch tube for switching and switching power supplies, and the general buttons on the operation panel, may be damaged due to long-term use or improper operation, resulting in the robot not working properly.

Other hardware issues: These include limit switch failures, toggle switch damage, control line disconnection, damage to relays or relay circuit boards, AC contactors, and other issues that can cause the robot to not work as intended.

Improper maintenance: If the robot is not properly cleaned and lubricated, it can cause parts to wear or clog, which in turn can affect its performance.

In order to prevent these failures, it is recommended to regularly maintain and inspect the palletizing robot to ensure that all parts are in working order. At the same time, for faulty robots, professional maintenance personnel should be contacted in time for inspection and maintenance to ensure that they can resume normal work as soon as possible.

扫一扫关注公众号