码垛机器人的维护保养是一个综合且细致的过程,涉及多个方面的检查和维护工作。以下是一些具体的维护保养步骤和要点:

在进行维护保养时,务必注意安全操作规程,避免因操作不当而导致的人身伤害或设备损坏。同时,记录维护保养情况,以便跟踪机器人的运行状态和维护历史。

通过定期的维护保养工作,可以确保码垛机器人的正常运行、延长其使用寿命和提高生产效率。建议根据实际情况和制造商的建议,制定合适的维护保养计划,并严格执行。

The maintenance of palletizing robots is a comprehensive and meticulous process that involves multiple aspects of inspection and maintenance. Here are some specific maintenance steps and key points:

Daily cleaning: Before leaving work every day, use a dry rag or brush to clean the appearance and key parts of the robot to ensure that there is no accumulation of dust, debris or oil. Special attention is paid to cleaning critical components such as sensors and cameras to maintain their sensitivity and accuracy.

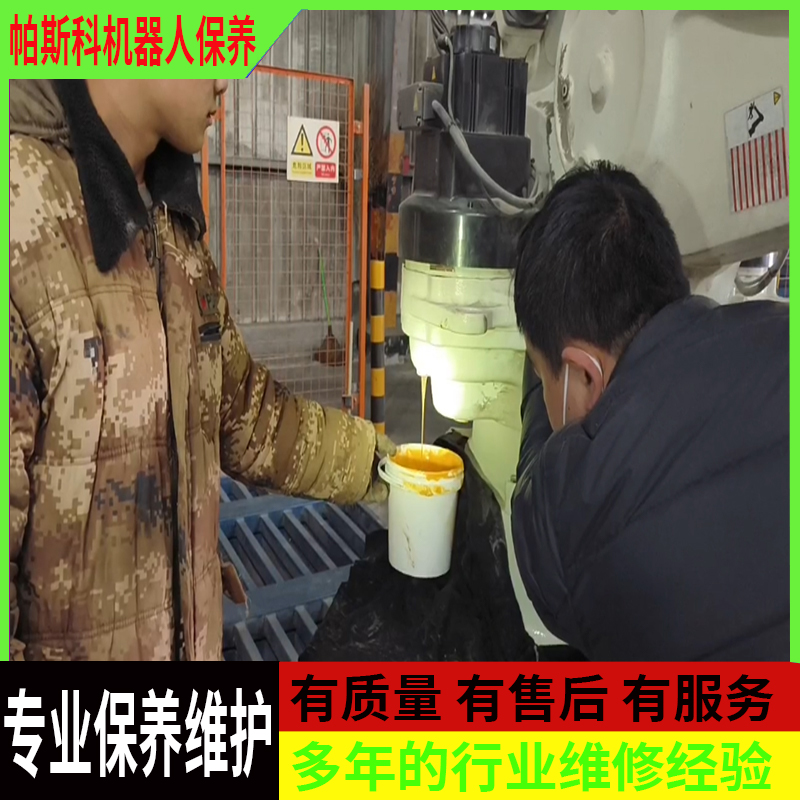

Lubrication maintenance: Regularly lubricate key parts of the robot, such as bearings, guide rails, etc. Select the appropriate lubricant and add it in accordance with the manufacturer's recommended dosage. At the same time, check the working condition of the lubrication system to ensure the cleanliness and adequacy of the lubricating oil.

Electrical System Inspection: Check the connection of electrical wiring and cables to ensure that there is no looseness, breakage or aging. Use professional tools to check the working status of electrical components, such as motors, switches, sensors, etc., to ensure that they are working properly.

Mechanical parts inspection: Inspect the mechanical parts of the robot, such as transmission systems, gears, chains, etc. Check its tightness, wear and operating status, and identify and deal with potential problems in a timely manner.

Pneumatic system maintenance: check whether the system pressure of the pneumatic pipeline is normal, and whether there is leakage of the cylinder, pipeline and connectors. Frequently check the working condition of the triplet in the system, release water and refuel in time to ensure the stability and reliability of the gas circuit system.

Preventative maintenance: Develop a preventive maintenance plan based on the use of the robot and the manufacturer's recommendations. This includes measures such as regular replacement of wear parts, adjustment of mechanical parameters, and updating of software systems to prevent potential failures.

When carrying out maintenance, it is important to pay attention to the safety operation procedures to avoid personal injury or equipment damage caused by improper operation. At the same time, the maintenance status is recorded in order to track the operating status and maintenance history of the robot.

Through regular maintenance work, the normal operation of the palletizing robot can be ensured, its service life can be extended and the production efficiency can be improved. It is recommended to formulate a suitable maintenance plan according to the actual situation and the manufacturer's advice, and strictly implement it.

扫一扫关注公众号