工业机器人的日常维护保养措施对于确保其正常运行、延长使用寿命以及提高生产效率至关重要。以下是一些关键的日常维护保养措施:

此外,对于特殊应用环境的工业机器人,如高温、高湿或腐蚀性环境,还需采取额外的保养措施,如加强防护涂层、使用耐腐蚀材料等。

综上所述,工业机器人的日常维护保养涉及多个方面,包括清洁、润滑、紧固、电气系统检查等。通过采取这些措施,可以确保工业机器人的稳定运行,提高生产效率,并延长使用寿命。

Routine maintenance measures for industrial robots are essential to ensure their proper operation, extend their service life, and improve production efficiency. Here are some key routine maintenance measures:

Cleaning & Dusting: Regularly clean the robot's enclosure with a professional cleaner to remove dust and stains from the surface. At the same time, keep the area around the robot clean and tidy to avoid being affected by contaminants such as dust, grease, liquids, etc. Particular attention is paid to cleaning critical areas such as joints, drives, and sensors to avoid dust accumulation affecting performance.

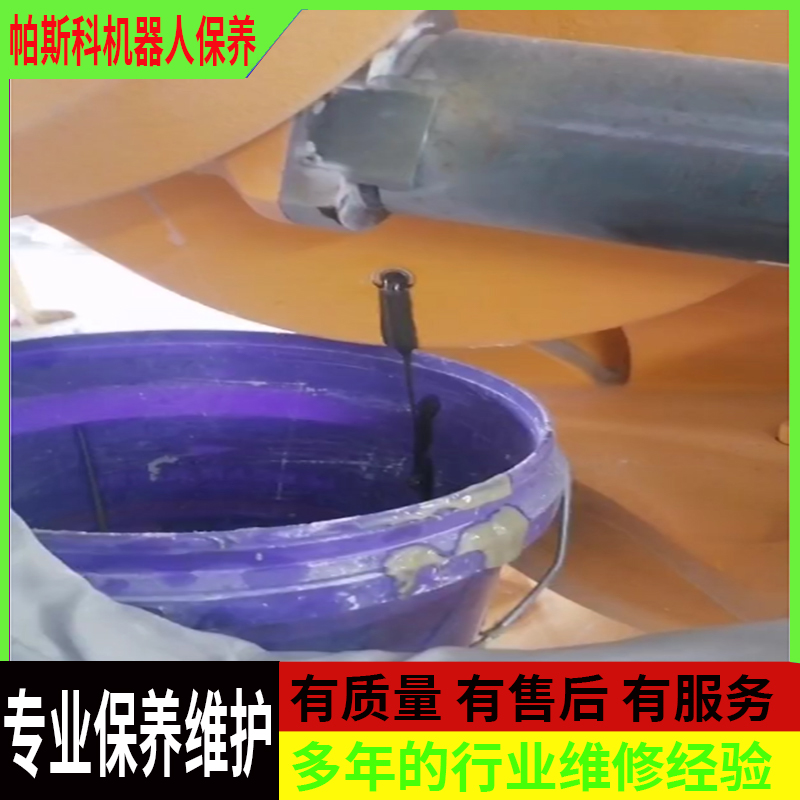

Lubrication maintenance: Regularly lubricate the joints, bearings and other moving parts of the robot according to the manufacturer's recommendations. Choose the right lubricant and ensure that it is evenly applied to reduce friction and wear. In addition, it is necessary to check the oil level of the lubrication system and the cleanliness of the oil, and replenish or replace the lubricating oil in time.

Fastener inspection: Regularly inspect the robot's fasteners, such as screws, nuts, etc., to ensure that they are tight and not loose. Loose fasteners can cause the device to become unstable or malfunction.

Electrical system inspection: check whether the power cord and signal cord are well connected and have no damage or aging. At the same time, check whether the electrical components such as sensors and motors are working properly to ensure the accuracy and stability of signal transmission. For the wiring and connectors of the control system, also check regularly to ensure that there is no loosening or damage.

Functional testing and calibration: Regularly perform functional testing and accuracy calibration on industrial robots to ensure that they operate accurately according to preset procedures. If anomalies or deviations are found, they can be adjusted and repaired in a timely manner.

Safety protection inspection: ensure that the safety protection devices of the robot are intact and effective, such as safety doors, protective covers, etc. At the same time, check whether safety devices such as the emergency stop button are working properly so that they can be quickly shut down in case of emergency.

Establish maintenance records: Every time you carry out daily maintenance, you should record the content and results of maintenance. This helps to track the maintenance of the equipment, identify potential problems in a timely manner, and provide a basis for subsequent repairs and replacements.

In addition, for industrial robots in special application environments, such as high temperature, high humidity or corrosive environments, additional maintenance measures are required, such as strengthening protective coatings and using corrosion-resistant materials.

To sum up, the daily maintenance of industrial robots involves many aspects, including cleaning, lubrication, fastening, electrical system inspection, etc. By taking these measures, it is possible to ensure the stable operation of industrial robots, improve production efficiency, and extend their service life.

扫一扫关注公众号