码垛机器人的润滑油脂维护保养是确保其长期稳定运行和延长使用寿命的关键步骤。以下是针对码垛机器人润滑油脂维护保养的详细指导:

此外,还需要注意以下几点:

总之,码垛机器人的润滑油脂维护保养是机器人维护保养的重要环节之一。通过选择合适的油脂、定期更换、清洗与加注以及定期检查与记录等措施,可以确保机器人的润滑系统正常运行,延长机器人的使用寿命。

Grease maintenance of palletizing robots is a key step to ensure their long-term stable operation and extended service life. The following is a detailed guide for the maintenance of grease for palletizing robots:

Choose the right grease: Choose the right grease according to the model of the robot, the conditions of use and the manufacturer's recommendations. Make sure that the selected grease has good lubricating properties, resistance to oxidation, resistance to wear and corrosion.

Replace the grease regularly: Failure to replace the grease for a long time will cause the grease to deteriorate and clog the bearing, which will increase wear and shorten the service life of the robot. Therefore, the grease should be changed regularly to ensure the lubrication of all parts of the robot. The specific replacement cycle should be determined based on the use of the robot and the manufacturer's recommendations.

Cleaning and filling: Before replacing grease, the bearing and lubrication system should be thoroughly cleaned to remove old grease and impurities. Then, follow the manufacturer's instructions and add the right amount of fresh grease. Be careful not to over-fill so as not to affect the normal operation of the robot.

Inspection and recording: After each grease change, the lubrication of the robot should be checked to ensure that all parts are well lubricated. At the same time, the time, type and quantity of grease changes are recorded for subsequent tracking and management.

In addition, there are a few things to keep in mind:

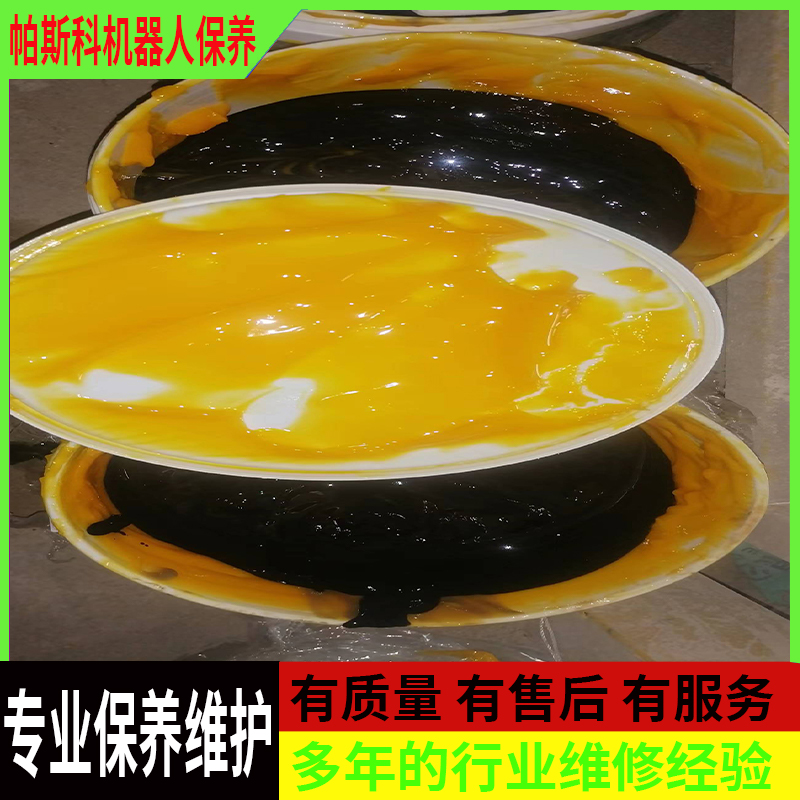

Check the condition of the grease regularly: By looking at the color, smell and texture of the grease, you can tell if the grease has deteriorated or needs to be replaced.

Keep it clean: Make sure that the robot's lubrication system and surrounding environment are clean and avoid dust, impurities, etc. from entering the lubrication system.

Professional training: Carry out professional training for operation and maintenance personnel to familiarize them with the maintenance methods of the robot to ensure correct and safe operation.

In short, the maintenance of grease and grease of palletizing robots is one of the important links in robot maintenance. By selecting the right grease, replacing it regularly, cleaning and filling it up, and checking and recording it regularly, you can ensure that the robot's lubrication system is functioning properly and that the robot's service life is extended.

扫一扫关注公众号