更换机器人润滑油的步骤如下:

请注意,不同型号的机器人可能有不同的换油步骤和要求,因此在操作前请务必参考机器人的使用说明书或咨询专业的机器人维护人员。此外,务必使用规定型号的润滑油,因为错误的润滑油可能会导致机器人性能下降或损坏。在操作过程中,务必注意安全,避免发生意外。

另外,机器人的润滑系统除了定期更换润滑油外,还需要进行日常的清洁和维护,以确保其正常运行和延长使用寿命。因此,建议定期对机器人进行维护和保养,包括清洁、润滑、紧固、检查和校准等操作。

The steps to change the robot oil are as follows:

Preparation: First, turn off the power of the robot and wait for the robot to cool down. Prepare the tools you need, such as wrenches, funnels, cleaning cloths, etc., and the right amount of robot-specific lube.

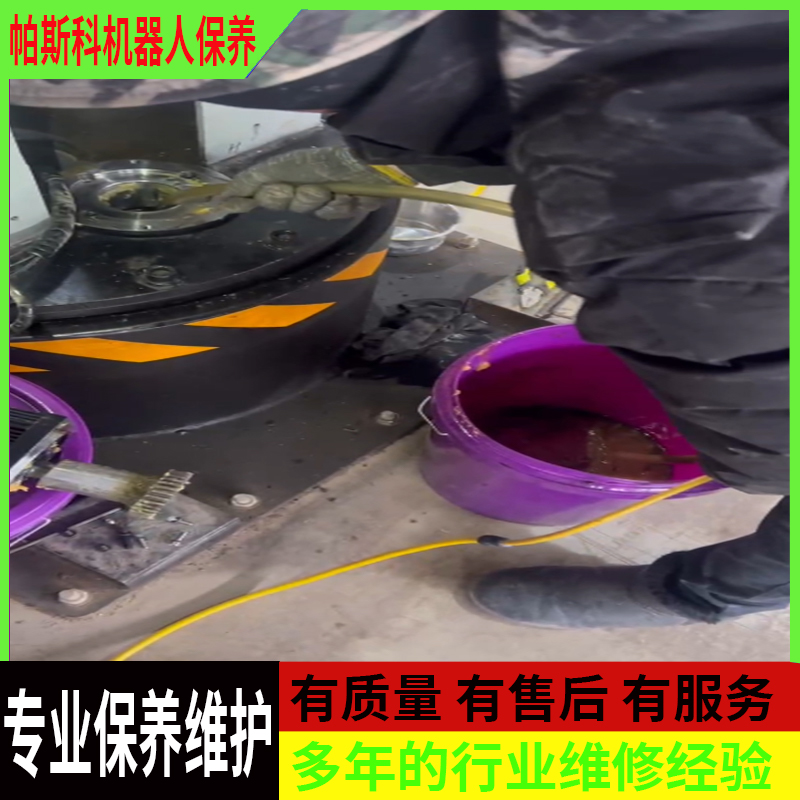

Drain the old oil: Find the oil drain and oil filler port of the robot, open the oil drain port, and let the old oil drain completely. At the same time, use a cleaning cloth to clean up impurities and old oil around the oil drain and oil filler.

Add new oil: Use a funnel to pour a new robot-specific lube into the filler until the oil level reaches the specified standard line. During the refueling process, impurities should be avoided from entering the refueling port.

Confirm lubrication: After completing the refueling, turn on the robot again and run the robot for a period of time to ensure that the new oil can fully lubricate all parts. At the same time, observe whether the robot has abnormal sounds, vibrations or oil leaks.

Cleaning & Inspection: Reseal the drain and oil filler ports, and use a cleaning cloth to clean the surface and surroundings of the robot from grease stains. At the same time, check other parts of the robot for parts that need to be maintained or replaced.

Please note that different models of robots may have different oil change steps and requirements, so be sure to refer to the robot's instruction manual or consult a professional robot maintenance personnel before operation. In addition, it is important to use the prescribed type of lubricant, as the wrong lubricant may cause degradation or damage to the robot's performance. During operation, it is important to pay attention to safety to avoid accidents.

In addition, in addition to regular oil changes, the robot's lubrication system also needs to be cleaned and maintained daily to ensure its normal operation and extended service life. Therefore, it is recommended to carry out regular maintenance and maintenance of the robot, including cleaning, lubrication, fastening, inspection and calibration.

扫一扫关注公众号