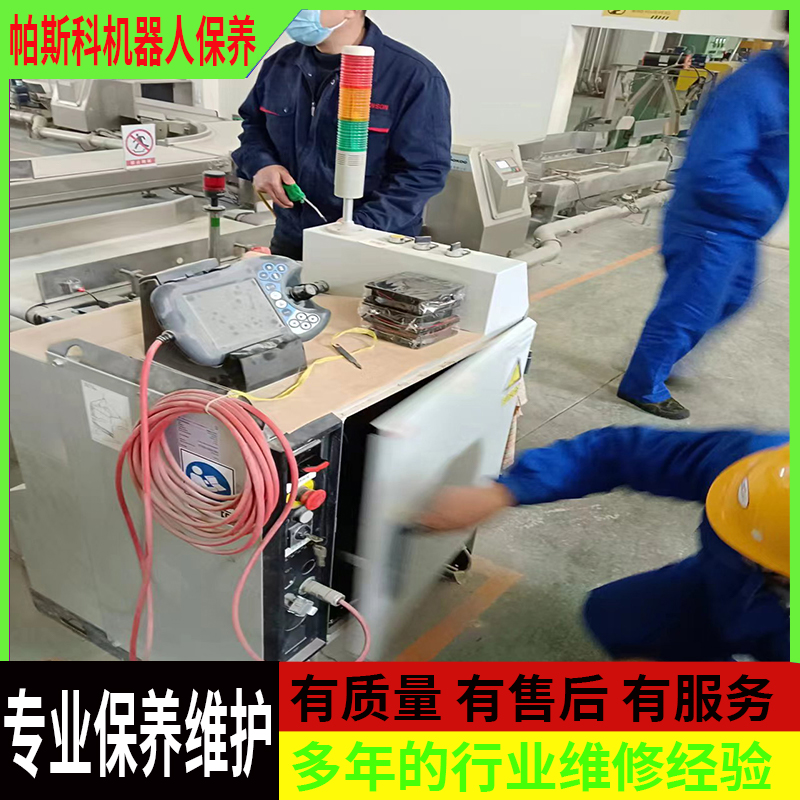

码垛机器人的保养方式包括以下几个关键步骤:

遵循以上保养方式,可以确保码垛机器人的正常运行,延长其使用寿命,提高生产效率。同时,也有助于减少因设备故障导致的生产中断和维修成本。

The maintenance method of the palletizing robot includes the following key steps:

Daily cleaning: Before leaving work every day, the palletizing robot should be carefully cleaned. Use a relatively dry rag to clean the appearance of the robot, and for areas that are difficult to clean, you can use a brush to clean them. Make sure the surface of the robot is free of dust, grease, and other impurities. In addition, attention should also be paid to the cleaning of the inside of the robot, but this usually requires a professional to operate.

Inspect machine parts: Regularly inspect all parts of the robot, including cables, sensors, motors, and mechanical parts, etc., to ensure that all parts are firmly connected and will not loosen or fall off. If there is any abnormality or problem, it should be repaired or replaced in time.

Lubrication maintenance: Lubricant is added to machine parts on a regular basis based on the use of the robot and the manufacturer's recommendations. This helps to ensure smooth operation of machine components and reduces wear and tear between components. At the same time, it is also necessary to regularly check whether the lubricating oil of the vacuum pump is dirty or less, and if necessary, it should be replaced or added in time.

Preventive maintenance: In order to extend the life of the palletizing robot, preventive maintenance should also be carried out. This includes regular replacement of wear parts, such as filters, seals, etc., to prevent failures due to wear or aging. In addition, the parameters of the robot are adjusted according to the actual operation situation, and the equipment is calibrated to ensure that its positioning and movement accuracy meet the requirements.

Safe operation: Safety norms should always be followed during maintenance and upkeep. For example, when cleaning and inspecting a robot, the power supply should be disconnected first to prevent accidental start-up. At the same time, use suitable professional tools for maintenance and upkeep work to avoid damage or accidents caused by the use of inappropriate tools.

Following the above maintenance methods can ensure the normal operation of the palletizing robot, prolong its service life, and improve production efficiency. At the same time, it also helps to reduce production interruptions and repair costs due to equipment failures.

扫一扫关注公众号